[Waste Water Treatment] [ALTERNATIVE DOCUMENTATION] Waste Water Treatment Using Electro Coagulation

PRELIMINARY SPECIFICATIONS - WORK IN PROGRESS

Desired Outcomes of this Project

Design and build a system that can treat waste water using Electro Coagulation.

Definitions

| Electrode | An electrode is a metallic contact through which electricity can pass. |

| Total Suspended Solids (TSS) | Solids in contaminated water that can be trapped by filtration processes. Also sometimes known as colloids. |

| Colloids | Colloids are insoluble particles that are larger than a molecule but smaller than particles that can be seen with naked eye. |

| Sludge | Semi-solid material that is produced as a by- |

Description

Electro Coagulation is a process of separating impurities, hazardous chemicals and bacteria from contaminated or waste or dirty water to make it reusable again. Electrocoagulation is performed by applying an electric current across metal plates (electrodes) that are submerged in contaminated water.

Contaminated water consists of suspended particles called colloids. In contaminated water, these particles can be organic particles like germs, bacteria, algae, and inorganic particles like emulsified oils, clay, silt or hazardous chemicals. These suspended particles have surface charges that allows them to stay suspended in contaminated water.

Why this is important

What this project needs to move forward

We need these skills to move this project forward:

Hands on Builders - someone that can build this project, do side by side comparisons on a converted and standard batteries, take measurements, run load tests, and record results.

- Physics Majors - Students and contributors who are enthusiastic about building waste water treatment systems.

- Structural Engineers - Contributors who can build structures that are compact. Knowledge of flow behavior of waste water or other viscous liquids is an added advantage.

Apply now if you are interested in participating in this project or visit the Project Management board (here) and jump right in.

Preliminary Research and Documentation

The following research and documentation is meant to get this project started. Please consider this a work in progress. Significant work is needed to move this project forward.

Components

- Electrodes (2) - Stainless steel or iron or aluminum electrodes.

- DC Power Supply - A power supply unit that can provide a 5V DC power to the circuit.

- Multimeter - A multimeter to check voltage and ampere o electricity.

- Wires - To connect the electrodes to the DC power supply.

- Waste water - 1 liter of a homogeneous mixture of water, oil, vegetable juice, soil, meat, and alcohol.

- Gloves and protective eye wear.

Method

An electrocoagulation unit consists of an anode and a cathode that are connected to a DC power supply. When contaminated water flows into an electrocoagulation unit, the following reactions occur:

- From the anode, metallic ions are released into the contaminated water.

- On the cathode, water is hydrolyzed, forming hydrogen gas (H2) and hydroxyl (OH) particles.

- Electrons move from the cathode to the anode. This destabilizes surface charges on the suspended solids (colloids).

When the electrons destabilize the surface charges on these suspended particles, the metal ions, along with the hydroxyl particles form complex compounds called flocs that includes metals and other contaminants. Colloids and emulsified oils combine with these flocs to form sludge. Depending on the chemical composition of the floc, the sludge can either rise to the top and float or sink to the bottom. Sludge can be removed physically from the sludge tanks and disposed off in an eco-friendly manner.

The water is now available for further filtering or reuse.

Flocculation

The process of water filtration also involves a process called flocculation. This process is usually done before the water is released into the electrocoagulation unit. Flocculants are chemicals that are added to contaminated water to form flocs and sludge.

Lab work

Experiment 1 (April 15 - 20:00 hrs IST) :

400 ml of water with soil and cooking oil was mixed to form a solution. 2 rusted electrodes were placed in the solution. A battery of 1.5 V was applied to the solution. The following image shows the electrocoagulation of the mixture at 11:00 hrs IST on April 16. The particles have separated. The oils have moved to the surface. The soil has moved to the bottom of the container. The middle part is clean water. The cathode is a bolt. The anode is a clamp from a lightning struck cable. More investigations on the chemical compositions is required.

Experiment 2 (April 16 - 20:00 hrs IST):

Red coloring powder was mixed in water with salt and lemon. A 1.5V battery was applied at 19:30 hours. These are the findings:

The mixture is thick and the water is red in color. This is a picture from 19:30 hours. A DC voltage of 1.5 volts was applied. The cathode was a bolt made of iron. The anode was a piece of clamp struck by lightning.

The following picture is from 08:00 on April 17th.

The DC current has separated the particles which have formed compounds and have settled at the bottom. The water on the top needs to be filtered and can be reused for gardening purpose directly. Further treatment can be done to make it potable or even drinking water.

Testing the Electrocoagulation System

Pass DC power to the electrocoagulation system at different intervals of time of 4, 8 and 12 hours. At each time interval, measure the amount of sludge that is recovered from the sludge tanks and test the final water for TSS.

Proposed location for prototype installation

A location has been selected for testing various prototypes involved with water, such as testing a "jacuzzi" style tub, a shower that recycles its water, mad a toilet that uses electrocoagulation.

An extension has been built off a container which forms part of teh Ocean Builders factory in Linton Bay.

The inside of the container has the locations for the toilet, urinal, shower and jazuzzi.

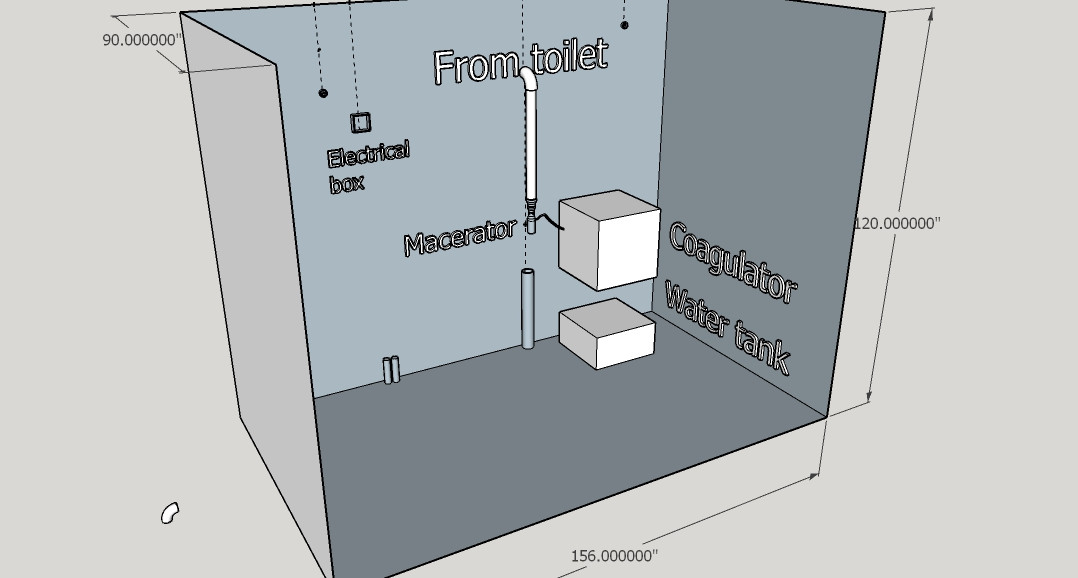

The proposed configuration of the coagulaor and related hardware located inside the extension.

Documenting Results and Recommendations

Documenting Results

The outcomes of this project must give a recommendation of how much water can be recovered based on these parameters:

- Amount of additives in the water. for example, 400 grams of additives in 1 liter of water.

- Electrocoagulation time (interval of time that DC current is passed in the mixture).

- How much DC power is used during the process.

- Amount of sludge separated after electrocoagulation.

- Amount of water recovered after electrocoagulation.

Sample report (not accurate)

Waste water 1 - 400 grams of additives (oil, soil, meat, vegetable juice and alcohol) added in 1 liter of water.

| Time | Sludge separated | Water recovered |

| 4 hours | 100 grams | 300 ml |

| 8 hours | 150 grams | 400 ml |

| 12 hours | 350 grams | 750 ml |

Publishing Recommendations

A detailed report of the recommendation must accompany the results. The recommendation must specify the following:

- Quantity of additives added in 1 liter of water

- Sludge separated over each interval of time

- Water recovered over each interval of time

- Precautions on handling electrodes, DC power supply

- Testing and measuring equipment

Useful Links:

https://en.wikipedia.org/wiki/Electrocoagulation

https://watervisioninc.com/electrocoagulation/overview/

https://www.watertectonics.com/electrocoagulation/

Turning salt water into drinking water, without harming the environment

Kit Ordered: https://www.makewater.org/storefront/coagulator

Excellent video demo: https://www.youtube.com/watch?v=VG7AZuZcRZI

This project is being developed as an open-source project with the following licensing:

- Software: GPL-3.0 - https://www.gnu.org/licenses/gpl-3.0.en.html

- Hardware, Design & other Intellectual Property: CC-BY-SA-4.0 - https://creativecommons.org/licenses/by-sa/4.0/